Daikin J Series Manuel de service

Naviguer en ligne ou télécharger Manuel de service pour Climatiseurs à système divisé Daikin J Series. Daikin J Series Service manual Manuel d'utilisatio

- Page / 162

- Table des matières

- MARQUE LIVRES

- Inverter Pair 1

- FTK(X)-J / RK(X)-J Series 1

- Table of Contents i 2

- Table of Contents iii 4

- 1. Introduction 6

- 1.1.3 Inspection after Repair 8

- 1.1.4 Using Icons 9

- 1.1.5 Using Icons List 9

- List of Function 10

- 1. Functions 11

- 1. Specifications 13

- Si04-115 Specifications 14

- Specification 5 14

- 220 - 230 - 240V, 50Hz 14

- Specifications Si04-115 15

- 6 Specification 15

- 220V, 60Hz 15

- Specification 7 16

- 230V, 50Hz 16

- 1.2 Heat Pump 17

- Specification 9 18

- 10 Specification 19

- Control PCB (1) 22

- P.C.B Detail 25

- Main Function 17 26

- 1. General Functionality 27

- Main Function 19 28

- 1.2 Operating Modes 29

- 1.3 Frequency Principle 30

- 1.4 Defrost Control 32

- 1.5 Forced Operation Mode 33

- Main Function 25 34

- (R1906) (R1906) 35

- Main Function 27 36

- J type 33 39 0 - 9 10 60 36

- 1.9 General Functions 37

- Timer operation 38

- Night set circuit on 38

- 1.10 Intelligent Eye 39

- Main Function 31 40

- 32 Main Function 41

- 1.12 Automatic Operation 42

- 1.13 Input Current Control 43

- Main Function 37 46

- 1.18 Wet Operation Protection 48

- 40 Main Function 49

- System Configuration 50

- Safety Precautions 51

- Installation 52

- Names of Parts 53

- Preparation Before Operation 55

- To stop: 57

- POWERFUL 58

- Operation 58

- Adjusting the 59

- ATTENTION 59

- Adjusting the louvre 59

- Timer Operation 60

- Good Sleep Cooling Operation 61

- (G-SLEEP) 61

- Intelligent Eye 62

- Care and Cleaning 63

- Trouble Shooting 65

- 3P062625-4B 68

- Instruction Si04-115 69

- 60 System Configuration 69

- Service Diagnosis 61 70

- Operation lamp (green) 71

- Air outlet 71

- (R19431) 73

- 5. Trouble shooting 75

- Si04-115 Trouble shooting 76

- Service Diagnosis 67 76

- Abnormality 77

- Service Diagnosis 69 78

- 5.5 Faulty Indoor Unit PCB 79

- 5.6 Faulty Indoor Unit PCB 80

- Circuit Boards 81

- Service Diagnosis 73 82

- Trouble shooting Si04-115 83

- 74 Service Diagnosis 83

- Service Diagnosis 75 84

- 76 Service Diagnosis 85

- 5.12 Output Overcurrent 86

- 78 Service Diagnosis 87

- 5.13 Faulty Outdoor Unit PCB 88

- 80 Service Diagnosis 89

- Service Diagnosis 81 90

- 82 Service Diagnosis 91

- Service Diagnosis 83 92

- Troubleshooting 93

- Check No.17 93

- Refer to P.92 93

- 6. Check 94

- Check Si04-115 95

- 86 Service Diagnosis 95

- Service Diagnosis 87 96

- Service Diagnosis 89 98

- 6.1.5 Rectifier Check 99

- Si04-115 Check 100

- Service Diagnosis 91 100

- 6.1.9 Hall IC Check 101

- Si04-115 102

- Removal Procedure 93 102

- 1.1 Removal of Air Filter 103

- Removal Procedure 95 104

- Step Procedure Points 104

- 96 Removal Procedure 105

- 1.2 Removal of Front Grille 106

- 98 Removal Procedure 107

- Removal Procedure 99 108

- Removal Procedure 101 110

- Removal Procedure 103 112

- Pull up the switch box 113

- A hook is provided on the 113

- 106 Removal Procedure 115

- Removal Procedure 107 116

- 1.5 Removal of Heat Exchanger 117

- 110 Removal Procedure 119

- 1.6 Install of Drain Plug 120

- 112 Removal Procedure 121

- Disengage hook 122

- Loosen the hexagon 122

- Remove the motor and 123

- Remove a screw on the 123

- Removal Procedure 115 124

- 116 Removal Procedure 125

- The front plate and the 127

- Sectional view at the front 127

- Removal Procedure 119 128

- 120 Removal Procedure 129

- 122 Removal Procedure 131

- Removal Procedure 123 132

- 124 Removal Procedure 133

- Slide the MID upward 134

- Remove the fan motor 136

- Removal Procedure 131 140

- 2.7 Removal of Four-way Valve 141

- 2.8 Removal of Compressor 143

- 136 Removal Procedure 145

- Others 137 146

- 1.1 Explanation 147

- Others Si04-115 149

- 140 Others 149

- Appendix 141 150

- 1. Piping Diagram 151

- INDOOR UNIT 151

- 4D019960D 151

- OUTDOOR UNIT 152

- 3D019958B 152

- 3D019956B 152

- 3D019959B 153

- 3D019957B 153

- 2. Wiring Diagram 154

- 3D020027F 154

- 3D020026E 155

- 3D028631B 156

- 3D028628B 157

- IndexIndex 158

- Drawings & Flow Charts 160

- Printed in Japan 02/2002 AK 162

Résumé du contenu

Si04-115Inverter PairFTK(X)-J / RK(X)-J Series[Applied Models]!!!!Inverter Pair : Cooling Only !!!!Inverter Pair : Heat PumpServiceManual

Si04-115List of Function 1Part 1 List of Function1.Functions...

Si04-115 CheckService Diagnosis 916.1.7 Power Supply Waveforms CheckCheck No.13 Measure the power supply waveform between pins 1 and 3 on the terminal

Check Si04-11592 Service Diagnosis6.1.9 Hall IC CheckCheck No.16 1. Check the connector connection.2. With the power ON, operation OFF, and the connec

Si04-115Removal Procedure 93Part 7Part 7Part 7Part 7Removal ProcedureRemoval ProcedureRemoval ProcedureRemoval Procedure1. For FTK25J, FTK35J, FTX25J,

For FTK25J, FTK35J, FTX25J, FTX35J Si04-11594 Removal Procedure1. For FTK25J, FTK35J, FTX25J, FTX35J1.1 Removal of Air FilterProcedure Warning Be

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 953. Opening and shutting front panel 1Hook a finger onto the projection part provided on

For FTK25J, FTK35J, FTX25J, FTX35J Si04-11596 Removal Procedure3When restoring the air filter, make sure that the projection parts on the panel are in

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 971.2 Removal of Front GrilleProcedure Warning Be sure to wait 10 minutes or more af

For FTK25J, FTK35J, FTX25J, FTX35J Si04-11598 Removal Procedure2. Removal of front grille assembly.1Remove the two screws, in the right and the left,

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 993The front grille can be removed in a manner to pull out the upper part forward and lif

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115100 Removal Procedure1.3 Removal of Horizontal Blade and Vertical BladeProcedure Warning Be sure to wa

Functions Si04-1152 List of Function1. Functions1.1 Indoor Unit and Outdoor UnitCategory FunctionsFTK25·35J SeriesRK25·35J SeriesFTX25·35J SeriesRX25·

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 101"For restoring. 1. Since the key pattern hook is provided on the left side, inser

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115102 Removal Procedure1.4 Removal of Switch Box, PC Board and Swing MotorProcedure Warning Be sure to w

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 1035Remove a screw on the terminal strip."The switch box can be removed instead of d

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115104 Removal Procedure7Pull up the switch box forward to remove."A hook is provided on the behind.Step

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 1052. Removal of printed circuit board1Remove the shelter.2Disengage the front plate of t

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115106 Removal Procedure4Disengage the four knobs on the back of the display printed circuit board.5Display pr

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 1076Control printed circuit board."The control printed circuit board is integrated w

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115108 Removal Procedure1.5 Removal of Heat ExchangerProcedure Warning Be sure to wait 10 minutes or more

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 1094Disengage the hooks of the pipe retainer on the back.5Pull auxiliary pipe forward to

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115110 Removal Procedure7Lift and remove heat exchanger. Caution!When removing or re-installing heat exchanger

Si04-115Printed Circuit Board Connector Wiring Diagram 3Part 2Part 2Part 2Part 2SpecificationSpecificationSpecificationSpecification1. Specifications.

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 1111.6 Install of Drain PlugProcedure Warning Be sure to wait 10 minutes or more aft

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115112 Removal Procedure1.7 Removal of Fan Rotor and MotorProcedure Warning Be sure to wait 10 minutes or

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 1132Disengage hook.3Loosen the hexagon head set screw on the fan rotor.Step Procedure Poi

For FTK25J, FTK35J, FTX25J, FTX35J Si04-115114 Removal Procedure4Remove the motor and fan rotor.5Remove a screw on the left side panel.Step Procedure

Si04-115 For FTK25J, FTK35J, FTX25J, FTX35JRemoval Procedure 1156Disengage a hook from the backward.7Since the fan bearing is made of rubber, push it

For RK25J, RK35J, RX25J, RX35J Si04-115116 Removal Procedure2. For RK25J, RK35J, RX25J, RX35J2.1 Removal of External CasingProcedure Warning Be su

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1172The top plate and the front plate are constructed in a monoblock. Remove the three screws

For RK25J, RK35J, RX25J, RX35J Si04-115118 Removal Procedure5The front plate and the left side plate can be removed when the one fixed screw is remove

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1192.2 Removal of Bell mouth and Left Side PlateProcedure Warning Be sure to turn off all

For RK25J, RK35J, RX25J, RX35J Si04-115120 Removal Procedure2.3 Removal of PC Board and Switch BoxProcedure Warning Be sure to turn off all power

Specifications Si04-1154 Specification1. Specifications1.1 Cooling Only220 - 230 - 240V, 50Hz220 - 230V, 60HzNotes:" MAX. interunit piping length

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1212Remove the four screws fixing the printed circuit board.3Disconnect the wire harness.4Dis

For RK25J, RK35J, RX25J, RX35J Si04-115122 Removal Procedure5Undo the eight hooks and the printed circuit board can be disengaged."The printed ci

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1237The printed circuit board can completely be released.3. Remove the switch box.1Remove the

For RK25J, RK35J, RX25J, RX35J Si04-115124 Removal Procedure2Lift and remove the switch box.4. Remove the molded interconnect device (MID).1Remove the

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1252Slide the MID upward and release.Step Procedure Points

For RK25J, RK35J, RX25J, RX35J Si04-115126 Removal Procedure2.4 Removal of Propeller Fan and Fan MotorProcedure Warning Be sure to turn off all po

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1274Remove the fan motor.Step Procedure Points

For RK25J, RK35J, RX25J, RX35J Si04-115128 Removal Procedure2.5 Removal of Compressor Noise Absorption PadProcedure Warning Be sure to turn off al

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1292Pull out the body of the noise absorption pad.3Pull out the top pad of the noise absorpti

For RK25J, RK35J, RX25J, RX35J Si04-115130 Removal Procedure2.6 Removal of Partition Plate and ReactorProcedure Warning Be sure to turn off all po

Si04-115 SpecificationsSpecification 5220 - 230 - 240V, 50HzNotes:" MAX. interunit piping length: 25m" MAX. interunit height difference: 15m

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1314When restoring the partition plate, put the hook into the bottom frame.2. To remove the r

For RK25J, RK35J, RX25J, RX35J Si04-115132 Removal Procedure2.7 Removal of Four-way ValveProcedure Warning Be sure to turn off all power supplies

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 133"Begin your work after recognizing complete empty of refrigerant in the refrigerant c

For RK25J, RK35J, RX25J, RX35J Si04-115134 Removal Procedure2.8 Removal of CompressorProcedure Warning Be sure to turn off all power supplies at l

Si04-115 For RK25J, RK35J, RX25J, RX35JRemoval Procedure 1352The compressor’s mounting nut to be removed is one piece.WarningSince it may happen that

For RK25J, RK35J, RX25J, RX35J Si04-115136 Removal Procedure

Si04-115Others 137Part 8Others1. Others ...1381.1 Explan

Others Si04-115138 Others1. Others1.1 Explanation1.1.1 Test Run from the Remote Controller (For Heat Pump Model Only)Trial Operation and Testing1. Mea

Si04-115 OthersOthers 1391.1.2 Method of Operating Air Conditioners Individually (When Two Units are Installed in One Room)For Cooling Only and Heat P

Others Si04-115140 Others1.1.5 Adjusting the Angle of the Intelligent-eye Sensor"Once installation of the indoor unit is complete, adjust the ang

Specifications Si04-1156 Specification220V, 60HzNotes:" MAX. interunit piping length: 25m" MAX. interunit height difference: 15m" Amoun

Si04-115Appendix 141Part 9Part 9Part 9Part 9AppendixAppendixAppendixAppendix1.Piping Diagram...

Piping Diagram Si04-115142 Appendix1. Piping Diagram1.1 Indoor Unit1.1.1 Cooling Only and Heat PumpFIELD PIPINGFIELD PIPINGCROSS FLOW FANFAN MOTORON H

Si04-115 Piping DiagramAppendix 1431.2 Outdoor Unit1.2.1 Cooling OnlyRK25JVE9, RK25JVEA9, RK25JVET9, RK25JV1NB9RK35JVE9, RK35JVEA9, RK35JVET9, RK35JV1

Piping Diagram Si04-115144 Appendix1.2.2 Heat PumpRX25JVEA9, RX25JVET9, RX25JV1NB9RX35JVEA9, RX35JVET9, RX35JV1NB9VALVE9.5CuTFOUR WAYON:COOLING7.9CuT7

Si04-115 Wiring DiagramAppendix 1452. Wiring Diagram2.1 Indoor Unit2.1.1 Cooling OnlyFTK25JVE9, FTK25JVEA9, FTK25JVET9, FTK25JV1NB9FTK35JVE9, FTK35JVE

Wiring Diagram Si04-115146 Appendix2.1.2 Heat PumpFTX25JVEA9, FTX25JVET9, FTX25JV1NB9FTX35JVEA9, FTX35JVET9, FTX35JV1NB9NOTEADDRESS JUMPER IS MARKED &

Si04-115 Wiring DiagramAppendix 1472.2 Outdoor Unit2.2.1 Cooling OnlyRK25JVE9, RK25JVEA9, RK25JVET9RK35JVE9, RK35JVEA9, RK35JVET9RK25JV1NB9, RK35JV1NB

Wiring Diagram Si04-115148 Appendix2.2.2 Heat PumpRX25JVEA9, RX25JVET9RX35JVEA9, RX35JVET9RX25JV1NB9, RX35JV1NB9FIELD WIRING.NLindoorLMRCW,MRLDB1CT1M1

Si04-115Index iIndexIndexIndexIndexAA1 ...66A5 ...

Si04-115ii IndexPower Supply Waveforms Check ...91Power transistor check ...85Power Tr

Si04-115 SpecificationsSpecification 7230V, 50HzNotes:" MAX. interunit piping length: 25m" MAX. interunit height difference: 15m" Amoun

Si04-115Drawings & Flow Charts iiiDrawings & Flow ChartsDrawings & Flow ChartsDrawings & Flow ChartsDrawings & Flow ChartsAAdjusti

Si04-115iv Drawings & Flow ChartsRemoval of Switch Box, PC Board and Swing Motor ...102SSignal Transmissio

Head office:Umeda Center Bldg., 4-12, Nakazaki-Nishi 2-chome,Kita-ku, Osaka, 530-8323 JapanTokyo office:Shinjuku Sumitomo Bldg., 6-1 Nishi-Shinjuku2-c

Specifications Si04-1158 Specification1.2 Heat Pump220-230-240V, 50Hz / 220-230V, 60HzNotes:" MAX. interunit piping length: 15m" MAX. interu

Si04-115 SpecificationsSpecification 9220V, 60HzNotes:" MAX. interunit piping length: 15m" MAX. interunit height difference: 15m" Amoun

Specifications Si04-11510 Specification230V, 50HzNotes:" MAX. interunit piping length: 15m" MAX. interunit height difference: 15m" Amou

Si04-115Table of Contents iInverter PairInverter PairInverter PairInverter PairFTK(X)-J / RK(X)-J SeriesFTK(X)-J / RK(X)-J SeriesFTK(X)-J / RK(X)-J Se

Si04-115Printed Circuit Board Connector Wiring Diagram 11Part 3Part 3Part 3Part 3Printed Circuit BoardPrinted Circuit BoardPrinted Circuit BoardPrinte

Printed Circuit Board Connector Wiring Diagram and Name Si04-11512 Printed Circuit Board Connector Wiring Diagram1. Printed Circuit Board Connector Wi

Si04-115 Printed Circuit Board Connector Wiring Diagram and NamePrinted Circuit Board Connector Wiring Diagram 13Control PCB (1)(R1895)Control P C B (

Printed Circuit Board Connector Wiring Diagram and Name Si04-11514 Printed Circuit Board Connector Wiring DiagramP.C.B (1) (Control P.C.B) Detail

Si04-115 Printed Circuit Board Connector Wiring Diagram and NamePrinted Circuit Board Connector Wiring Diagram 151.2 RK25/35J Series, RX25/35J SeriesP

Printed Circuit Board Connector Wiring Diagram and Name Si04-11516 Printed Circuit Board Connector Wiring DiagramP.C.B Detail

Si04-115Main Function 17Part 4Part 4Part 4Part 4Main FunctionMain FunctionMain FunctionMain Function1.General Functionality...

General Functionality Si04-11518 Main Function1. General Functionality1.1 Functions of ThermistorsLocation of thermistorsThe thermistors on the drawin

Si04-115 General FunctionalityMain Function 19Frequency controlled functionsThe following table shows the different functions, which are controlled by

General Functionality Si04-11520 Main Function1.2 Operating ModesModes There are two operating modes:"normal operating mode"forced operating

Si04-115ii Table of ContentsInverter Pair FTK(X)-J / RK(X)-J Series... i1. Introduction ...

Si04-115 General FunctionalityMain Function 211.3 Frequency PrincipleMain control parametersThe compressor is frequency-controlled during normal opera

General Functionality Si04-11522 Main FunctionInverter features The inverter provides the following features:"The regulating capacity can be chan

Si04-115 General FunctionalityMain Function 231.4 Defrost Control Principle Defrost control is carried out by reversing the cycle from heating to cool

General Functionality Si04-11524 Main Function1.5 Forced Operation ModeForced modeA way to enter the test operation mode by a remote controller.1. Set

Si04-115 General FunctionalityMain Function 251.6 Wide-angle Flaps, Diffuser, Louveres and AutoswingOutline of the actionIt can be commanded for J typ

General Functionality Si04-11526 Main Function1.7 Fan Speed Control for Indoor UnitsControl mode The airflow rate can be automatically controlled depe

Si04-115 General FunctionalityMain Function 271.8 Fan Speed Control for Outdoor UnitsControl The following drawing explains the fan speed control:Fan

General Functionality Si04-11528 Main Function1.9 General FunctionsPre-heat operationWhen the equipment has stopped and t[outside] < 11.5°C, the co

Si04-115 General FunctionalityMain Function 29"The frequency command for every zone is stated below.(Please note that an operation will not carry

General Functionality Si04-11530 Main Function1.10 Intelligent EyeOutline The function that detects existence of humans in the air-conditioned room an

Si04-115Table of Contents iii2. Problem Symptoms and Measures...633. Service Check Function ...

Si04-115 General FunctionalityMain Function 31conditions to conduct thermostat-off depending on the room temperature. In or after this forty minutes,

General Functionality Si04-11532 Main Function1.11 Good Sleep Cooling ControlOutline The function to create deep sleeping and to offer good sleep by a

Si04-115 General FunctionalityMain Function 331.12 Automatic OperationThe unit automatically switches the operation mode to cooling or heating to main

General Functionality Si04-11534 Main Function1.13 Input Current ControlOutline The frequency control will be carried out so that the input current wi

Si04-115 General FunctionalityMain Function 351.14 Freeze Protection Function in CoolingOutline During Cooling/Dry operation, when the heat exchanger’

General Functionality Si04-11536 Main Function1.15 Peak-Cut Control FunctionOutline In a heating operation, there will be anxiety that a head pressure

Si04-115 General FunctionalityMain Function 371.16 Four-Way Valve Function CompensationOutline When the initial start of compressors is required after

General Functionality Si04-11538 Main Function1.17 Compressor Protection FunctionOutline An refrigeration oil level descent and progression of the dil

Si04-115 General FunctionalityMain Function 391.18 Wet Operation ProtectionOutline The lower limit of output frequency is limited in two steps in acco

General Functionality Si04-11540 Main Function1.19 Dew Condensation Sweating Prevention FunctionOutline During Cooling/Dry operation, when the heat ex

Si04-115iv Table of ContentsPart 9 Appendix... 1411. Piping Diagram...

Si04-115System Configuration 41Part 5System Configuration1. Instruction...

Instruction Si04-11542 System Configuration1. Instruction1.1 FTK25 / 35J, FTX25 / 35J2Safety Precautions Read the following warnings and cautions car

Si04-115 InstructionSystem Configuration 433To prevent inter-ference, place it at least 1 m away.A place with good ventilationAir outletAir inletWallI

Instruction Si04-11544 System Configuration4ONOFFAir purifying filterFront grilleIndicator lampsGrille tabIntelligent Eye lamp (green)Operation lamp (

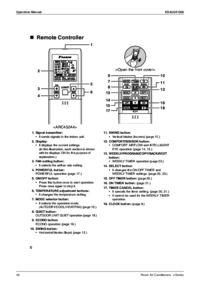

Si04-115 InstructionSystem Configuration 455CONAMPMAMPMTEMPON/OFFMODE -SLEEPSENSORONOFFTIMERFA NSWINGCANCELPOWERFULLTransmitterIt sends signals to

Instruction Si04-11546 System Configuration6Setting the batteriesOperating the remote controllerTo use the remote controller, aim the transmitter at t

Si04-115 InstructionSystem Configuration 477Holding down ( ) or ( ) buttonrapidly increases or decreases the time display.Tips for saving energyBe

Instruction Si04-11548 System Configuration8The air conditioner operates with the settings of yourchoice.From the next time on, the air conditioner wi

Si04-115 InstructionSystem Configuration 49POWERFUL operation quickly maximizes the cooling(heating) effect in any operation mode. You can get themaxi

Instruction Si04-11550 System Configuration10In DRY mode or COOL modeIn HEAT or FAN modeWhen stop operationUpper limit in coolingLower limit in coolin

Si04-115 Introductionv1. Introduction1.1 Safety CautionsCautions and Warnings"Be sure to read the following safety cautions before conducting rep

Si04-115 InstructionSystem Configuration 5111ATTENTIONNotes on OFF TIMER● NIGHT SET MODEWhen the OFF TIMER is set, the air conditioner automaticallyad

Instruction Si04-11552 System Configuration12•The "Good Sleep Cooling Operation" makes the 1/f Fluctuating Temperature.It brings you comfort

Si04-115 InstructionSystem Configuration 5313Press SENSOR While the air conditioneris operating. (The Sensor lamp lights up.) To cancel the “Int

Instruction Si04-11554 System Configuration14Air filterAir purifyingfilter frame• Hold the recessed parts of the frame and unhook the four claws.CAUTI

Si04-115 InstructionSystem Configuration 5515CheckCheck that the base, stand and otherfittings of the outdoor unit are not decayedor corroded.Check th

Instruction Si04-11556 System Configuration16CaseOperation does not start soon.When ON/OFF button waspressed soon after operationwas stopped.When the

Si04-115 InstructionSystem Configuration 5717Check againPlease check again before calling a repair person.Trouble ShootingCaseThe air conditioner does

Instruction Si04-11558 System ConfigurationWARNING When an abnormality (such as a burning smell) occurs, stop operation andturn the breaker OFF.Conti

Si04-115 InstructionSystem Configuration 5919●●●●● Fault diagnosisMEANINGNORMALREFRIGEMENT SHORTAGEPOWER FACTOR MODULE ABNORMALITYINCORRECT INTERUNIT

Instruction Si04-11560 System Configuration

Introduction Si04-115vi1.1.2 Cautions Regarding Products after RepairCautionDo not repair the electrical components with wet hands.Working on the equi

Si04-115Service Diagnosis 61Part 6Part 6Part 6Part 6Service DiagnosisService DiagnosisService DiagnosisService Diagnosis1. Caution for Diagnosis...

Caution for Diagnosis Si04-11562 Service Diagnosis1. Caution for Diagnosis1.1 Troubleshooting with The Operation LampThe Operation lamp flashes when a

Si04-115 Problem Symptoms and MeasuresService Diagnosis 632. Problem Symptoms and MeasuresProblem Symptom Check Item Details of Measure Page No. to be

Service Check Function Si04-11564 Service Diagnosis3. Service Check Function3.1 ARC423 SeriesIn the ARC423A series, the temperature display sections o

Si04-115 Code Indication on The Remote ControllerService Diagnosis 654. Code Indication on The Remote Controller4.1 Error Codes and Description of Fau

Trouble shooting Si04-11566 Service Diagnosis5. Trouble shooting5.1 Faulty PCBRemote Controller DisplayA1A1A1A1Indoor unit LED DisplayMethod of Malfun

Si04-115 Trouble shootingService Diagnosis 675.2 Operation Shutdown Due to High-Pressure Control or Freeze-Up Protection (Thermistor Activation)Remote

Trouble shooting Si04-11568 Service Diagnosis5.3 Operation Halt Due to Fan Motor (AC Motor) or Related AbnormalityRemote Controller DisplayA6A6A6A6Ind

Si04-115 Trouble shootingService Diagnosis 695.4 Operation Halt Due to Detection of Thermistor or Related AbnormalityRemote Controller DisplayC4, C4,

Trouble shooting Si04-11570 Service Diagnosis5.5 Faulty Indoor Unit PCBRemote Controller Display∗Indoor unit LED DisplayMethod of Malfunction Detectio

Si04-115 Introductionvii1.1.3 Inspection after RepairBe sure to use the specified cable to connect between the indoor and outdoor units. Make the conn

Si04-115 Trouble shootingService Diagnosis 715.6 Faulty Indoor Unit PCBRemote Controller Display∗Indoor unit LED DisplayMethod of Malfunction Detectio

Trouble shooting Si04-11572 Service Diagnosis5.7 Power Supply Abnormalities or Faulty Indoor Printed Circuit BoardsRemote Controller Display∗ or U4U4U

Si04-115 Trouble shootingService Diagnosis 735.8 Signal Transmission Error (Between Indoor and Outdoor Units)Remote Controller DisplayU4U4U4U4Indoor u

Trouble shooting Si04-11574 Service Diagnosis5.9 Operation Halt Due to Detection of CT ErrorRemote Controller DisplayH8H8H8H8Outdoor unit LED DisplayA

Si04-115 Trouble shootingService Diagnosis 755.10 Operation Halt Due to Thermistor Error or Disconnection DetectionRemote Controller DisplayJ3, J3,

Trouble shooting Si04-11576 Service Diagnosis5.11 Operation Halt Due to Compressor Startup ErrorRemote Controller DisplayE6E6E6E6Outdoor unit LED Disp

Si04-115 Trouble shootingService Diagnosis 775.12 Output OvercurrentRemote Controller DisplayL5L5L5L5Outdoor unit LED DisplayA 5Method of Malfunction

Trouble shooting Si04-11578 Service DiagnosisTroubleshooting ∗ Erroneous internal wiring can result in output overcurrent in some cases. If system sto

Si04-115 Trouble shootingService Diagnosis 795.13 Faulty Outdoor Unit PCBRemote Controller Display∗Outdoor unit LED DisplayA 4 Method of Malfunction D

Trouble shooting Si04-11580 Service Diagnosis5.14 Faulty Outdoor Unit PCB and Transmitting/Receiving CircuitRemote Controller Display∗Outdoor unit LED

Introduction Si04-115viii1.1.4 Using IconsIcons are used to attract the attention of the reader to specific information. The meaning of each icon is d

Si04-115 Trouble shootingService Diagnosis 815.15 Operation Halt Due to Detection of Input Over CurrentRemote Controller DisplayE8E8E8E8Outdoor unit L

Trouble shooting Si04-11582 Service DiagnosisTroubleshooting ∗ Internal wiring errors can cause an input over current. If the equipment stops due to

Si04-115 Trouble shootingService Diagnosis 835.16 Interrupt due to OL ActionRemote Controller DisplayE5Outdoor unit LED DisplayA 5Method of Malfunctio

Trouble shooting Si04-11584 Service DiagnosisTroubleshootingCheck No.17Refer to P.92Replace the OL.Reconnect the OL connector.Correct the OL harness a

Si04-115 CheckService Diagnosis 856. Check6.1 How to Check6.1.1 Power transistor checkCapacitor voltage checkCheck No.3 1. Power transistor checkNote:

Check Si04-11586 Service Diagnosis< Measuring positions >Take measurements at the power transistor (+) and (-) terminals in the same way as desc

Si04-115 CheckService Diagnosis 876.1.2 Power Transistor Output CheckCheck No.4 Measure the output current and voltage of the power transistor.Output

Check Si04-11588 Service Diagnosis6.1.3 Thermistor Resistance CheckCheck No.5 Remove the connectors of the thermistors on the PCB, and measure the res

Si04-115 CheckService Diagnosis 89For the models whose thermistor is directly equipped on the printed circuit board;6.1.4 Installation Condition Check

Check Si04-11590 Service Diagnosis6.1.5 Rectifier CheckCheck No.11There are several different terminal position patterns. Therefore, be sure to check

Plus de documents pour Climatiseurs à système divisé Daikin J Series

(6 pages)

(6 pages) (12 pages)

(12 pages) (24 pages)

(24 pages) (11 pages)

(11 pages)

Commentaires sur ces manuels